What is the npk compound fertilizer production line?

NPK fertilizer production process, a kind of compound fertilizer production line, is applicable for NPK fertilisers manufacturing. People can use it widely in making NPK compound fertilizer. The process is very easy to operate and manage. Meanwhile, the cost of machine for manufacturing of npk is very commercial and reasonable. We can be your best partner in the way to succeed. As a top grade selling npk fertilizers producer, Henan Waste To Fertilizer Machinery Company will provide optional npk compound fertilizer production line with high quality for you to make npk compound fertilizer with high nutrients. Welcome to visit our factory, open your new npk fertilizer production project.

Top two production methods of npk fertilizers

For manufacturing NPK fertilizer pellets, we offer you 2 types of npk compound production lines for reference. NPK fertilizer granulation line and NPK fertilizer granules blending line. Both of methods use the different production technology and fertilizer machine is different. Different new methods of producing better npk fertilizer and cheap equipment with high quality.

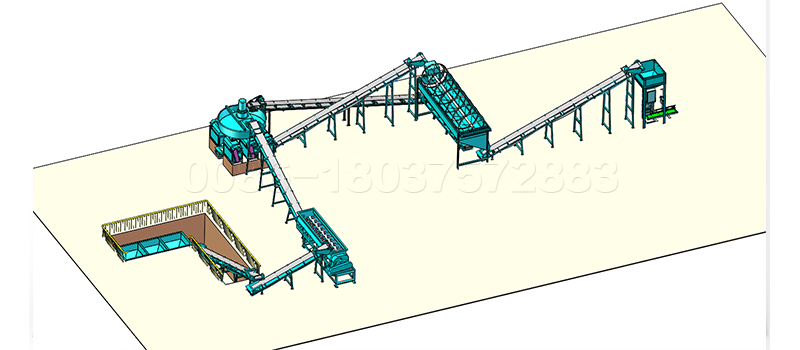

NPK compound granulation production line

It utilizes granulation technology for granulating. And the materials for pelletizing should be powders. Then our grnaulator can pelletize NPK fertilizer roller compactor. With the help of our brand fertilizer equipment, more qualified pellets can be produced. In addition, the different shapes of fertilizer pellets can be offered if you use our npk compound production line.

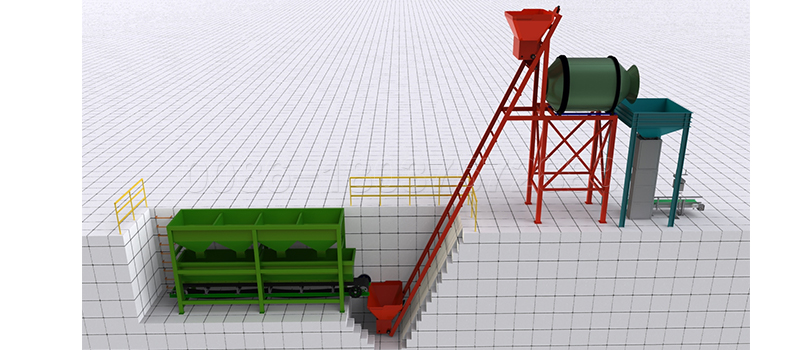

NPK fertilizer blending plant line

Relatively speaking, compared with NPK compound granulation production line, this process is more simple to make high quality NPK fertilizer pellets. The process only needs a BB fertilizer mixer. Before batching the N, P, K fertilizers according to your formula. Then by batching processing to mix pellets fertilizer evenly. Finally, using bagging machine to pack. The production line has the characteristics of low price, small floor space, large output and even mixing. What is more, the BB fertilizer equipment has various specifications, and people can choose it according to the different output per hour. And according to the mixed materials, it is divided into 2-5 kinds of materials. Which one do you need, please tell me as soon as possible. BB fertilizer process flow diagram: storage system- feeding system-metering system- conveying lifting-mixing-automatic packing and sewing package-finished belt transportation-computer control system.

How to make npk compound fertilizer by npk compound fertilizer production line and what are main equipment for npk compound production line ?

NPK fertilizer manufacturing process is an important process to make npk compound fertilizer line. The method can increase the plant population by high yield crops seed rate mixing npk fertilizer level. Generally speaking, it is very helpful for the growth of plants and rich soil to some extent. However, the process is very simple to make and save labor force cost. The steps are below:

The crushing process: It is the main step in the process of making NPK compound fertilizer. Therefore, we must put it in the first position. In order to make better npk granulators process, the materials need to crush evenly. In addition, our company can provide two kind of npk compound crusher, cage crusher, chain crusher. Both of then is the ideal tool for compound fertilizer crushing.

Using fertilizer npk mixing machine to mix: NPK mix fertilizer process is necessary. By mixing , the npk fertilizer powder can be stirred uniform, and enter the next granulation process. There are three kinds of mixer can be offered, horizontal mixer, double shafts horizontal mixer, single shaft mixer. All you can choose by its capacity. If you need small capacity, horizontal mixer and single shaft mixer is enough. On the contrary, double shaft horizontal mixer is best option.

What is the process after mixing?

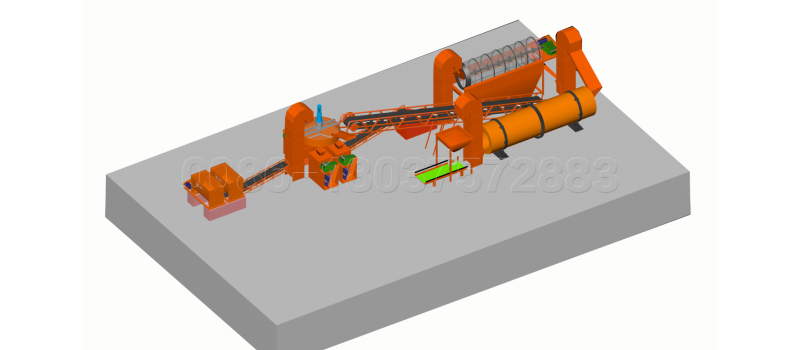

Making npk compound fertilizer pellets. Granulation is the main process in compound fertilizer production line. It marks the simple whole fertilizer production line is over. There are two kinds of methods to granulate fertilizer pellets, wet type, dry type. Meanwhile, choosing the npk granulation equipment according to different ways. There are three types, such as, double roller extrusion granular, disc granular, rotary drum granulator. Which one is suitable for you, please send us inquires.

NPK fertilizer drying and cooling. Drying and npk cooling machine is helpful to make pellets better. If you don’t dry and cool the pellets after granulation, both the granules temperature and moisture content will be too high, to the disadvantage of storing. Thus, using rotary drying and cooling machine are necessary. However, if you need double roller extrusion granulator to granulate, you don’t need to buy these two machines.

Finished npk compound fertilizer screening for coating. In order to screen qualified fertilizer or unqualified pellets, rotary screen machine is necessary equipment.

NPK compound fertilizer coating. It adopts powdering powder or liquid coating process, effectively preventing the lumps of npk compound fertilizer. By the way, you can make fertilizer pellets smoother and more convenient for transporting.

NPK fertilizer packing. This is the final step in all the process of NPK compound fertilizer production. It is an automatic packing scale for you to pack fertilizer conveniently. The automatic quantitative packing scale is designed for quantitative packing. Our designers divide it into double bucket packing scale and single bucket packing scale. Meanwhile, it has the characteristics of low scale height, compact structure, high efficient, novel appearance, easy installation and convenient maintenance. What is more, the quantitative precision of the system is 2‰.

What do you need to pay more attention while mixing the npk compound fertilizer powder?

Choosing chain crusher for chemical materials crushing

Obviously, there are two types to choose, vertical chain crusher and horizontal chain crusher. As we known, vertical chain crusher has single rotor, the latter has double rotor. But both of them can be suitable for crushing of block in compound fertilizer production and the crushing of return material in fertilizer production. Furthermore, the large blocks can be selected out until the powder is qualified.

Crushed semi npk materials batching for mixing

Using hot sale automatic batching equipment for batching powder materials is important. It can batch continually. In addition, its mainframe has PID regulation and alarm functions, which can realize the automatic control of a warehouse.

Straight npk compound fertilizer mixing for npk granulating

BB fertilizer mixer has a big difference from others. The materials should be pellets without crushing. It overcomes the mixtures chromatography and distribution phenomena caused by different proportion of raw materials and particle size. Finally, it improves the accuracy of the dosing. In addition, the process is so simple. After the mixing, npk compound fertilizer can be packed immediately. If you have small budget, this npk fertilizer production line is possible.