What is processed poultry manure by poultry composting machine ?

Poultry manure is kind of high farm fertilizer, including chicken manure, turkey manure, etc. Compared with pig manure, cow dung, it contains more multiple nutrient elements (N , K, P). However, all needs to be thoroughly decomposed before application. Meanwhile, it can inactivate parasites, eggs and infectious bacteria in the manure. Then, the processed poultry manure as fertilizer can begin to use. Relatively speaking, traditional composting method (anaerobic composting) is active for a long time. In order to accelerate poultry manure composting process to digest or decompose harmful matters, the use of poultry composting machine is necessary.

How to turn poultry manure to fertilizer during composting?

Poultry manure composting process is simple. However, aiming to fermentation of poultry manure, worthy detail you need to pay more attention. How to make compost from poultry manure we can provide valuable information for you.

Poultry manure collection. Poultry manure are made from poultry farms. Then, dry poultry manure by adding some auxiliary, such as sawdust, straw, etc or dewatering machine.

Making different shapes of poultry manure pile. Put the poultry manure on the different places, whether indoors or outdoors. Meanwhile, you can put them into large groove, make them into a long strip or place into organic fertilizer fermentation pin. Aiming to different forms, we can recommend different poultry compost machine for you.

Mixing the materials and turn, loosen, move regularly. Blending poultry manure evenly. Then using compost machine to turn and stir completely.

How to dry poultry manure before composting poultry?

Obviously, on the one hand, making poultry composting needs fresh poultry. on the other hands, adding some auxiliary to mix can adjust water content to 50%-60% preparing for composting and improve N nutrients for plants and soil to increase fertilizer effect. And generally speaking, there are two special material, biochar and sawdust. Both of them can prompt the poultry composting process. However, the water content of poultry manure can not reach the standard of water content. Therefore, poultry manure dewatering machine makes up for the deficiency. Compared with others, solid-liquid separator machine can separate poultry manure into liquid organic fertilizer and solid organic fertilizer. The process can make water content low below 35%. Finally, making a good preparation for poultry manure compost and granulation.

What kind of ways to reduce the smell from poultry manure?

Honest speaking, poultry litter has big smell. So how to remove smell from poultry manure is a difficulty. Now making poultry litter compost is available. After fermentation of poultry manure, the special smell can disappear gradually. In order to increase the speed of removing the smell, we recommend you to use poultry manure composting machine or organic fertilizer fermentation pot reducing the smell. Compared with two kinds, the effect of organic fertilizer fermentation pot is big but the price is most expensive. As for its only need 10 hours to complete the harmless treatment process. Meanwhile, it has the advantages of covering less (10-30 square meters), no pollution (closed fermentation), completely killing the pest eggs (can adjust the temperature from 80 degree to 110 degree), so it is the best choice to realize the resource utilization of waster materials for quaculture enterprise.

4 methods to the procedure of making compost from poultry manure

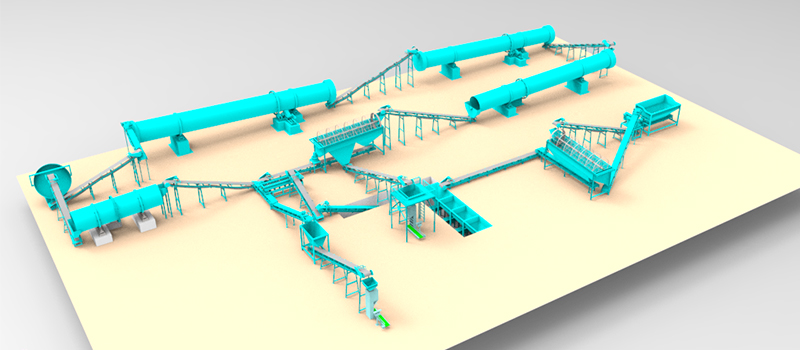

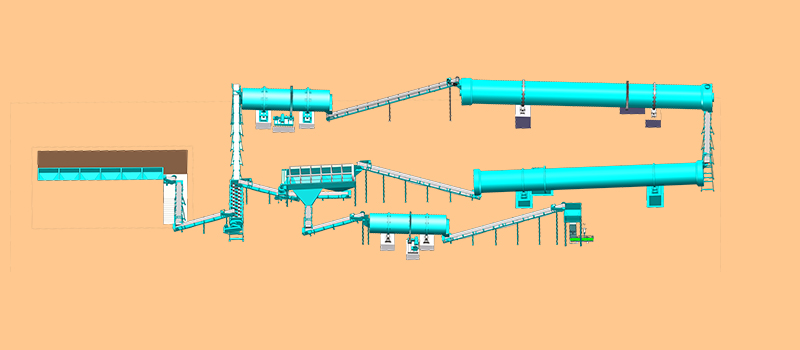

As mentioned above, regular turning is necessary during poultry compost machine. Compared with traditional composting, our composting machine can help you shorten the period, improve nutrients and reduce damage to the plants or soil. The choice of machine focuses on the different methods for placing poultry manure.

Compost facilities are aerated or unaerated and covered or not covered. Composting methods include passive piles, windrow composting static piles, and in vessel composting (in bins, beds, silos, transportable containers, and rotating drums).

- Passive piles

Passive piles are created by stacking materials in piles and allowing them to decompose over a long time with little managements simple, inexpensive method also has some disadvantages: the poultry manure pile can overheat and spontaneously combust; it can become anaerobic and release odors; it sits there for years, taking up valuable space; and it can look like a dumo and attract the dumping of unwanted materials. Passive piles can take a year or more to decompose, depending on the materials in the piles.

- Windrow composting

Windrow composting involves placing mixed materials in long, narrow piles and turning or agitating them regularly. It is the most common method to use for rapid composting of poultry manure. Windrows are typically 3 to 12 feet high, 10 to 12 feet wide, and hundreds of feet long. Windrows are formed using a front-end loader, and they are turned with this equipment or a specialized turning device. This method is more labor-intensive than aerated pile because some activity is performed on the site almost daily. In our company there are two kinds of poultry manure composting machine to provide aiming to the method, crawler type compost turner and moving type compost turner. Both of them can save time and labor force and improve poultry compost production efficiency and its quality significantly.

-

Groove composting

Groove composting needs to place mixed poultry manure into a groove. The groove are about 30 to 40m wide, 3 to 4 m long. Then when the temperature reach 60 to 70 degree, using groove type poultry manure compost turner, wheel type poultry manure compost turner, or chain plate type poultry manure compost turner to turn and loosen.then you can get high quality poultry manure compost.

- In-vessel composting

In-vessel composting refers to diverse group of methods that confine the poultry manure composting process within a container (aerobic fermentation pot), building, or vessel and uses a combination of forced aeration and mechanical turning to speed up the composting. Compared with windrow and aerated pile methods, those systems require less labor and land area and offer potentially better odor control, faster composting (in a matter of days as opposed to weeks0, and consistently good compost. However, in-vessel systems have high capital, operating, and maintenance costs.

Different method of making poultry manure depend on different technology used. Window and grove systems are comparable in xost, labor, management and speed of process. In-vessel composting is faster, but it has high capital cost. Which way is the best for you, pl choose one carefully.

Some benefits of poultry manure compost to soil and plants

Obviously, poultry manure compost is a kind of compost which can used as a soil incorporant, mulch, turf or other plant top dressing, an amendment to growing mixes, and a blend with topsoil.currently, the number one use of compost is in planting beds. It is predicated that compost will be used widely for field nursery production. For example, it can meet requirements for planting okra and bacillus.

- Improve soil structure by using composted poultry manure

- Prompt water infiltration and drought tolerance

- Improve root growth and yields

- Increase microbial and earthworm populations in soil

- Protect plants from disease

- Slowly release nutrients to plants

- Improve nutrient-holding capacity

- Increase ease of cultivation