Wat is nat granulasie masjien?

Oor die algemeen, daar is twee tipes tegnologieë vir granuleer in kunsmisbedryf, droë granulasie, nat granulasie. Mik op verskillende maniere, ons ingenieurs het behoorlike kunsmisgranuleerders vervaardig. In terme van tradisionele nat granulasie tegnologie, dit benodig hoë waterinhoud om nat kompos in korrels te maak. Dus, kunsmisgranulasie moet gedroog word, afgekoel, gestol. Daarby, daar is verskeie tipes om te kies, Nuwe tipe organiese kunsmisgranulator, roterende drom roergranulator, skyf granulasie masjien, roterende drom granulasie masjien, ens. Intussen, vir nat granulator kan dit nie net produseer nie organiese kunsmis korrels, maar ook saamgestelde kunsmisdeeltjies. Bowendien, relatief gesproke, dit speel 'n belangrike rol in kunsmisproduksielyn in ons maatskappy. Aan die ander kant, dit gebruik die mees ekovriendelike tegnieke, bied u baie hoë kwaliteit natgranulasiemasjiene. Watter soort natgranuleringstoerusting het jy nodig?

Hoekom kies ons hierdie metode vir nat granulering tot verpilling?

Natgranulasiemetode is al lank oor die hele wêreld gewild, dit is 'n moderne natgranuleringsmasjien en tegnologie is goed genoeg om die meeste materiale te hanteer, en kan sommige van die gebreke van nat pelletiseringstegniek uitmaak. Dit beteken dat een stel granualtors gebruik kan word vir 'n groot verskeidenheid grondstowwe tot lae koste vir jou besigheid. In vergelyking met droë granulasie metode, dit is die beste manier om kunsmiskorrels te verwerk. Intussen, dit is geriefliker om organiese kunsmis te produseer en saamgestelde kunsmis. Soos ons voorheen genoem het, gevorderde toerusting kan deesdae die probleem wat deur nat granulering veroorsaak word, neutraliseer. En ons natgranuleerders is bevoeg om die werk goed te doen.

Top 4 tipes natgranulasiemasjien te koop

Daar is vier tipes wat mense lok om vir jou besigheid of plaas te koop.

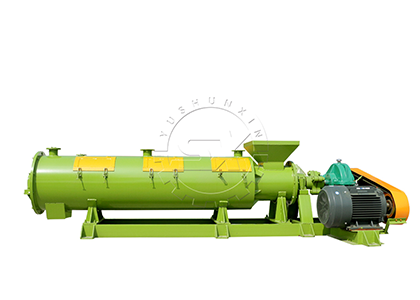

Nat roterende drom roergranulator

Ons maatskappy het nuut 'n roterende drom-roergranulator ontwikkel. Natuurlik, dit is gietmasjien wat materiaal kan maak in korrels in 'n spesifieke vorm. Dit maak gebruik van hoë spoed roterende meganiese roerkrag en die gevolglike aërodinamiese krag om fyn poeiermateriaal voortdurend die proses van die maak van korrels te maak. Intussen, dit moet meng, granuleer, bal en verdigting in die masjien, om die doel van granulering te bereik. Dit behoort aan die natgranuleringsmasjien in ons onderneming. Dit beteken deur 'n sekere hoeveelheid van die silinder, dit laat die basiese kunsmis volledig op chemiese manier reageer nadat dit in die silinder bevochtig is. Dan onder 'n sekere vloeistoffase, met behulp van roterende beweging van die silinder, dit het materiaalkorrels saam in balle gedruk. Wat is meer, dit het 'n hoë baltempo tot 85% en het 'n pragtige vorm vir jou behoeftes, selfs energie bespaar in sommige faktore.

Nuwe tipe nat organiese kunsmis granulator te koop

Relatief gesproke, nuwe tipe nat organiese kunsmisgranulator is 'n opgedateerde weergawe in ons maatskappy. Werkbeginsel tussen hulle is dieselfde. Nietemin, in terme van konstruksie, die verskille is dat die silinder nie gedraai kan word nie. En in terme van die materiaal, dit kan geskik wees vir moeilike materiale vir die vervaardiging van organiese kunsmismateriaal, soos koolstofswart, kaolien, en so aan. Intussen, die baltempo bereik tot 97% , especially big ball rate under 10%. And the shapes of balls are so beautiful which can meet you requirements. Dus, it can be a choice granulation equipment in our company for patent product. Why not think about it for your business?

Disc granulator for sale

Pan pelletizer (also called disc granulator) is the common one in granulation fertilizer industry. It is especially the ideal choice for mini npk fertilizer granulation plants. Because its smallest capacity is 0.5-1.0t/h. in addition, our disc granulation facility has the device of scraper, which helps you automated clean the machine during NPK fertilizer pelletizing process. Buitendien, there are three discharging ports in a disc granulator that is convenient for your NPK fertilizer pellets discontinuous production. Intussen, Wat is meer, it is suitable for making organic fertilizer pellets. Dus, tot 'n mate, it can reduce certain cost for fertilizer business.

20 t/h Rotary drum granulator: ZGZ-3210

This molding machine could produce 20-30 t/h compound fertilizer pellets. Intussen, the specific shape of fertilizer pellets is available for your requirements. And it is suitable for mass production of cold, hot granulation and high and low concentration compound fertilizer by means of wet granulation method. Through a certain amount of water or steam, the base fertilizer is fully reacted in chemical way after being wet in the cylinder body. Then under certain liquid conditions, the rotating motion of the cylinder is used to make the material particles get squeezed together into balls. Buitendien, different capacity drum granulation machine can be offered to you. How do you think about this one? Please tell us about your plan as soon as possible.

Wet granulation advantages and disadvantages to make fertilizer pellets

Soos ons hierbo genoem het, wet granulation is widely used in granulating organic fertilizer. Its application has some advantages and disadvantages in fertilizer industry.

Advantages:

- Process a broad range of starting materials, including all kinds of manure, horse manure, hoendermis, pig manure, ens

- Potential for high density granules. The high pellet rate can be reached up to 93%. Dus, it can help you reduce materials to waste for making fertilizer pellets. Intussen. Increasing income is possible.

- Wet granulation can make the structure of organic fertilizer pellets more compact.

- Large applications, especially in fertilizer production line. It plays an important role to produce fertilizer pellets.

- Muti-choice is possible. For different kinds of granulation machine, you choose them to use in terms of different unique features.

Disadvantages:

The process of granulation is quite complex. In vergelyking met droë granulasie metode, the standard water content of organic fertilizer pellets requires 10%. Dus, drying and cooling fertilizer pellets is necessary in the process of granulating. Nietemin, by the process, high quality fertilizer pellets can be manufactured in our company.

What is the wet granulator reasonable price in our company?

As a manufacturer of wet granualtor, our company can provide you with reasonable price. Why can we do that? Because we are direct supplier, not an agency in industry. Dus, you can get cheap wet granulation machine in terms of the parts cost. Then high output can increase income in suitable function or by fertilizer production process. Daarby, high quality wet granulation equipment is decisive effect. Terselfdertyd, to some extent it reduces the cost or budget of investment. Come here as soon as possible.