판매용 비료 과립 공장

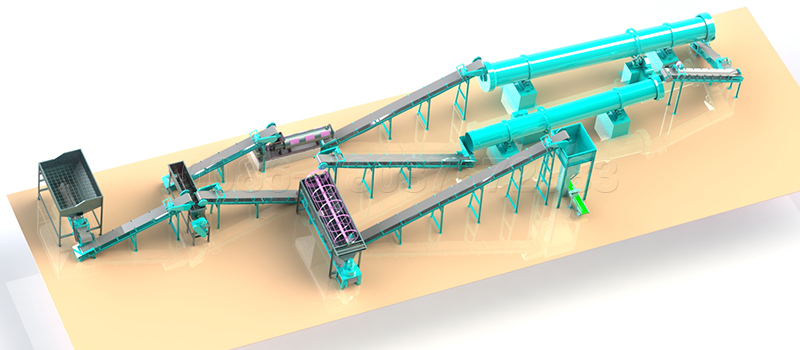

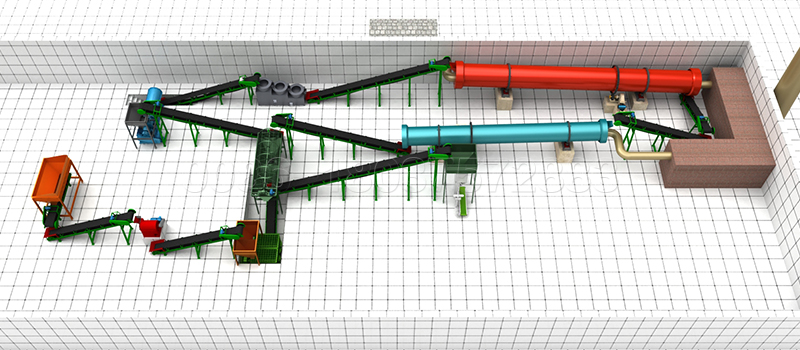

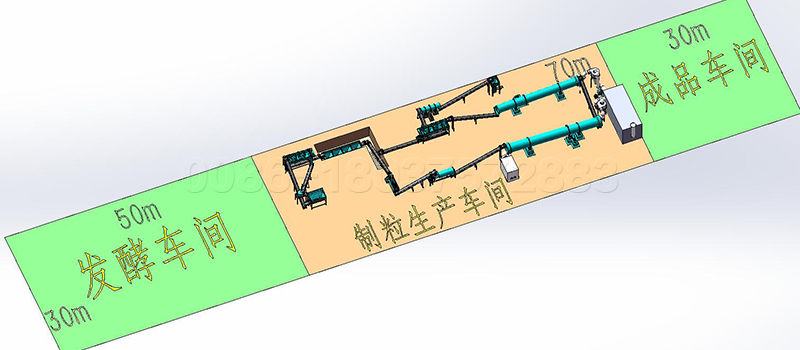

비료 사업을 시작하시겠습니까?? 비료산업에 입문한 신입이라면, 비료 과립화 공장을 시험해 보시기 바랍니다.. 비료 과립화 생산 라인은 재료를 유기 비료 및 복합 비료로 만드는 데 중요한 역할을 합니다.. 일반적으로, 그것은 큰 농장에서 인기가 있습니다, 소규모 설탕 산업, 포도주 양조장. 당사의 생산 라인은 농업 폐기물을 생태학적으로 처리하는 데 도움을 줄 수 있습니다., 설탕과 와인 잔류물, 가금류 분뇨, npk 비료, 등. 더 이상, 우리 회사, 전문 비료 장비 제조업체, 비료 알갱이로 만듦 식물을 위한 비료 기계의 전체 세트를 제공할 수 있습니다. 비료 과립 생산 라인에 관심이 있으시면, 빨리 연락주세요. 그 동안에, 우리 엔지니어들은 귀하에게 적합한 비료 과립화 플랜트 사업 프로젝트를 제안할 수 있습니다..

Three popular types of fertilizer granulation plant

후에 composting, fertilizer granulation is the most important step in the process of making fertilizer. In terms of different materials, we divide it into two famous 비료 생산 라인. As the blow saying:

Organic fertilizer granulation production line

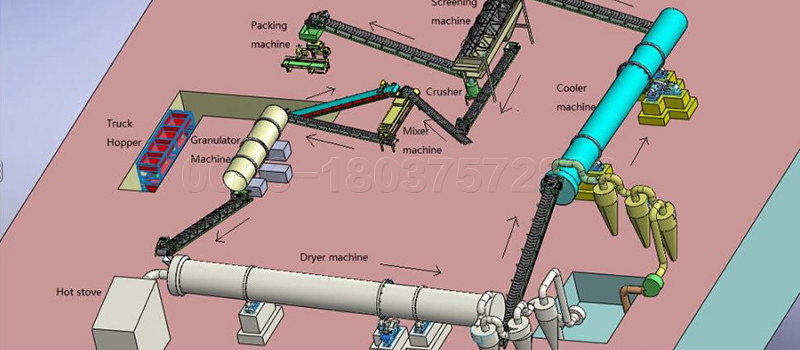

Granular organic fertilizer product procedure is very easy to operate and manage. How to make commercial granulated organic fertilizer becomes a key to succeed. what is organic fertilizer granulation production line? 확실히, it is a kind of organic fertilizer production line to produce organic fertilizer. And the materials are from manure, such as chicken manure, 말똥, cow dung and so on, or organic waste. Then convert those materials into organic fertilizer by composting. During the composing, it reduce the harm to the plants and soil. 후에 manure ferment, then you need further processing as a fertilizer businessman. 그러므로, our brand fertilizer granulation plant can give you a hope to make more benefits. Aiming to the materials, our engineers design suitable granulating equipment to make pellets. 예를 들어, 새로운 유기 유기 비료 입금기, 회전식 드럼 교반 조립기. Both of them use wet granulator method to produce organic fertilzier pellets.

Granulated compound npk fertilizer plant for sale

It belongs to a part of 복합비료 생산라인. It is a kind of compound fertilizer including 2 -3 elements, 좋다 NPK fertilizer production line. People cam widely use it all over the world. In terms of those materials, we provide two kinds of NPK compound fertilizer pelletizer to meet your requirements. During two machines, double roller extrusion granulator belongs to dry granulation equipment. 하지만, rotating granulator belongs to the wet granulation equipment. According to the differences between two machines, you can choose the best suitable fertilizer granulation plant to produce fertilizer.

Almighty pan granulation production line on sale

It is not only used for organic fertilizer granulation, but also compound fertilizer granulation. 그러므로, we call it almighty granulation equipment. The most important part is pan pelletizer which is the common one in granular fertilizer industry. Especially, it is the most ideal option for small scale fertilizer granulation plants. The whole smallest capacity of production line can reach 0.02-0.05 t/h.Therefore, for fertilizer granulation factory, it has some big advantages in the process of making organic fertilizer pellets or compound fertilizer mill. Over 93% granulation rate is available for the whole production line. 50 t/h disc granulator production line is optional. 게다가, cost of granulated fertilizers plant can be reductive. Disc granulator machine buying price is reasonable. 마지막으로, it is worth to invest as soon as possible.

Which method is most common in the commercial fertilizer wet or dry granulation of fertilizer granulation plant?

확실히, they belong to fertilizer granulation techniques in our company. Granulation technology is one of important process operation in the production of raw materials to get the proper size of granules or pellets. They are widely used in all aspects in the process of making fertilizer pellets. we have been researching and developing the technique to deal with more materials into fertilizer pellets. Those two methods are popular around the world and their purpose is to handle the material powders in industry. 그러므로, people can use it widely in modern fertilizer industry. 게다가, the production line is composed by several machines, composting making machine, 비료 분쇄기, mixer, rotary drum dryer, cooler, dispenser, screener, coating machine and so on.

Why not choose a suitable fertilizer granulation production line for your fertilizer factory?

If you are looking for fertilizer improved equipment granulator can produced 20-40 t/h, why not come to Fertilizer Machinery Company에 Henan 폐기물? If you desire to operate a pan granulator in the drop controlled engine at least 75% of the granules must be formed, why not come to our company? We will offer you the list plant & machinery for manufacturing organic or compound granule fertilizer. And design a fertilizer granulation plant project for you. 그 동안에, there are six significant feature for your inference.

- High granulating rate is necessary.

All our fertilizer granulation plant can have more than 93% balling rate. It reduce the waste of the livestock and decrease the cost.

- More choice in capacity.

Fertilizer granulation plant has different configurations in model, capacity, and appearance. Small scale fertilizer granulator process for sale in china is available, like pan granulation system.

- Wide application. Different materials can have different choice.

Especially, pan pellets production line can not be perfectly used to organic fertilizer pelltizing, such as poultry manure, 닭똥, 소똥, 등, but also used to compound fertilizer granulation, like npk fertilizer.

- Easy operation for workers.

전통적인 방법과 비교합니다, to some extent it saves labor forces and improve work efficiency. For its high automatic process, it can be easily to operate and control. 그러므로, it is the sunrise industry around he world.

- Long service life and high quality.

Following the operating procedures is very important for a fresher. 그 동안에, by this way it can keep it using for a long time. 반면에, it is in a high quality condition for adopting the steel as materials. 그러므로, our company is your best choice.